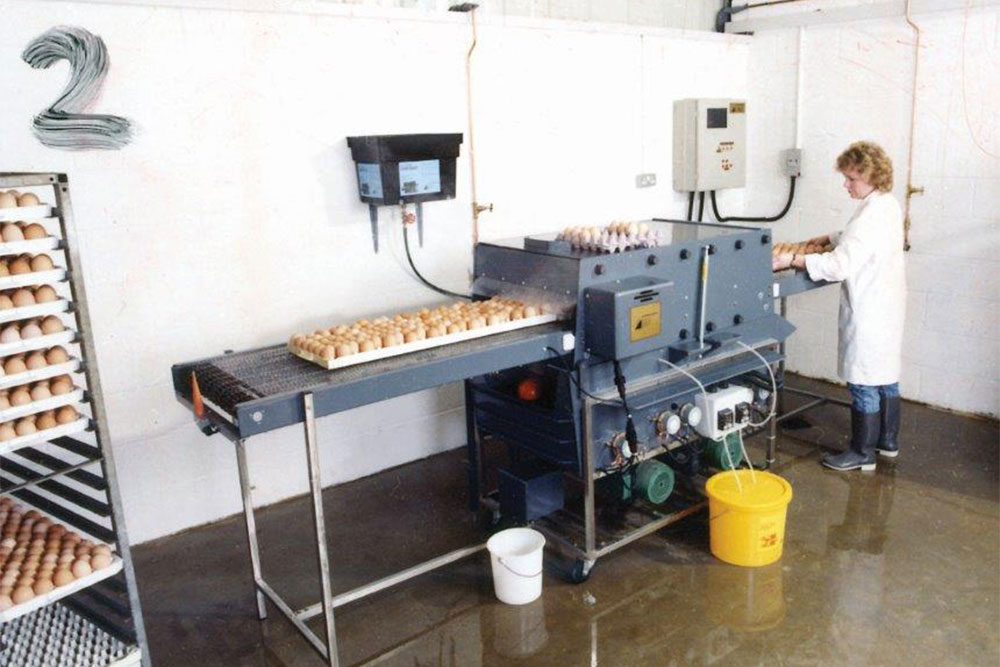

This machine comes standard with a dual belt speed system, with a slower belt speed option for processing, particularly soiled eggs.

Processing capacity of the Piccolo in eggs per hour:

Chicken eggs: 200-600/h

Duck eggs: 250-450/h

Game bird eggs: 600-1200/h

Dimensions

Length 100cm/40 inches

Width 65cm/26 inches

Height 60cm/24 inches

Power Requirements

E.U: 220-240v/50hz/25 amp

U.S.A: ac 208v/60hz/ 25 amp

Wash tank volume: 20 ltr./4.5 gals

Number of nozzles: 7

Heater: 1 x 3kw

Wash pumps: 1 (piccolo)

Processing capacity of the Super in eggs per hour:

Chicken eggs: 700-1,400/h

Duck eggs: 1,200/h

Game bird eggs: 3,000 /h

The Super is customizable to 180-degree dimensions.

Dimensions:

length: 92cm/36 inches

width: 70cm/28 inches

height: 50cm/20 inches

Power Requirements:

E.U. 220-240v/50hz/25 amp

U.S.A. ac208v/60hz/25 amp

Wash tank volume: 45 litre/10 gallons

Number of nozzles: 20

Number of heaters: 1 x 3 kw

Number of pumps: 1 x super

Options:

Mobile stand, Blow drying, Header tank fill, 14 inch egg on gravity feed, Pressure reduction valve, 90 degree load-off tray, Grader option, 180-Degree format

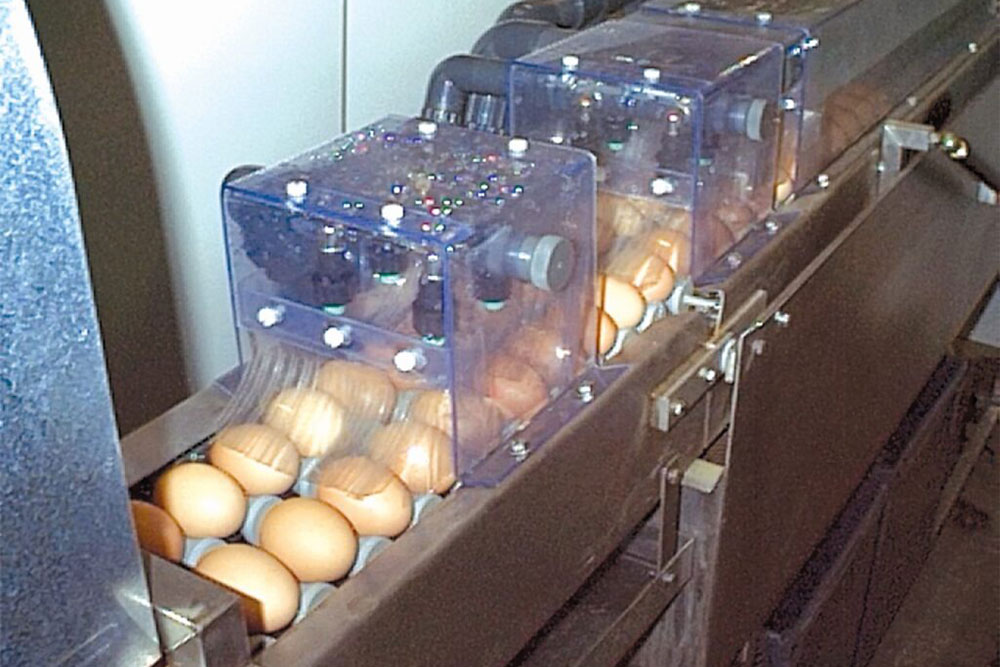

Processing capacity of the Super II in eggs per hour:

Chicken eggs: 3,000/h

Duck eggs: 3,000/h

Game bird eggs: 3,000 /h

Dimensions:

length: 92cm/36 inches

width: 70cm/28 inches

height: 50cm/20 inches

Power Requirements:

E.U. 220-240v/50hz/25 amp

U.S.A. ac208v/60hz/25 amp

Wash tank volume: 45 litre/10 gallons

Number of nozzles: 20

Number of heaters: 1 x 3 kw

Number of pumps: 1 x super

Options:

Mobile stand, Blow drying, Header tank fill, 14 inch egg on gravity feed, Pressure reduction valve, 90 degree load-off tray, Grader option, 180-Degree format